DeGroat Diesel

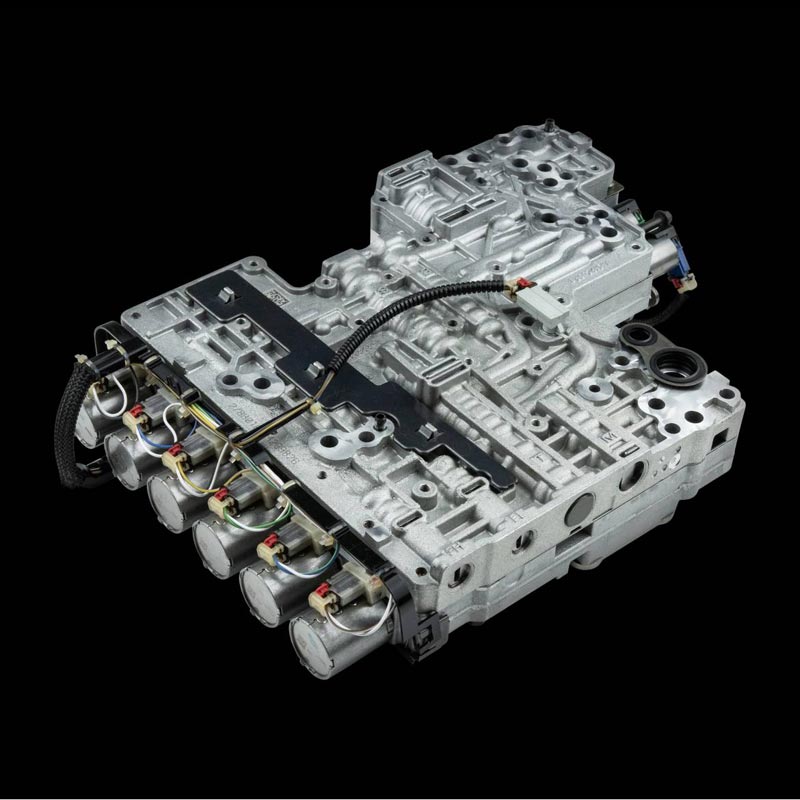

SUN COAST 10L1000-PVB PRO LOC VALVE BODY & PUMP KIT

SUN COAST 10L1000-PVB PRO LOC VALVE BODY & PUMP KIT

Couldn't load pickup availability

The Sun Coast 10L1000-PVB Pro Loc Valve Body & Pump Kit will enhance the performance of the Allison 10L1000 transmission in your GM 6.6L Duramax L5P. With the

SunCoast 10L1000 Pro Loc valve body, several key issues seen regarding the 10L1000 transmissions are addressed. This is not an approach that is simply upping the line

pressure in hopes of getting more clamping force. It's a multi-faceted approach addressing numerous key issues when exposing these units to more demanding driving

loads. These include drag racing, street racing, and heavy towing & hauling.

It is impressive that the factory 10L1000 transmission lock-up circuit can make converter lockup seem to smooth and uneventful. The level of refinement in its

involvement is unquestionably higher than what has hitherto been observed. Even though this feels good in terms of NVH (noise vibration harshness), it can become a

major issue when circumstances occur when the load demands exceed the vehicle's original design specifications or testing its limits.

The SunCoast 10L1000 Valve Body specifically looks to speed up the time from initial lock-up apply to zero turbine slip. To increase lockup holding and apply fluid

pressure, the torque converter clutch (TCC) valve is replaced, changing the lockup circuit. By modifying crucial oiling circuits to let the fluid to reach the TCC clutch, the

lockup oil transition time is also shortened, which reduces TCC clutch deterioration by enabling a faster application time. Improved reliability and performance are made

possible by lowering degradation per apply cycle.

The lubricating circuit is the next aspect to be addressed. The 10L1000 transmission's lubrication circuit is in charge of providing oil to the clutches, bushings, planets,

and other components. The lube circuit oil is distributed throughout the transmission from the factory at pressures as low as 6 PSI. Under normal load conditions, this is

completely fine. An increase in lubrication to planets, steels, and clutches is appropriate for handling the increasing demands and reducing heat in more demanding and

stressful situations.

This Valve Body specifically increases pressure in this circuit from 6 PSI to a whopping 20 PSI. This results in less frictional heat generated, which is a 250%

improvement over the factory calibration. In high-horsepower applications, premature failure can become more noticeable, although this heat reduction can help extend

the life of the transmission.

The regulator valve (latch valve) circuit is another modification made to the SunCoast Pro Loc 10L1000 Valve Body. The clutches are fully engaged by this oil circuit,

which provides full clutch line pressure. The regulator valve that is specifically targeted in factory form is in control of clutch packs A, B, C, and F.

As the first and most prominent clutch pack failure with the 10L1000 in higher horsepower or more demanding conditions, the "F" clutch is the main clutch pack concern.

In a factory 10L1000 valve body calibration, the regulator valve (latch valve) becomes fully engaged, allowing full fluid flow for engagement at 120 psi. When this

happens, the oncoming clutch pack delivers the maximum clamping force. The maximum static and dynamic holding capacity is determined when the clamping force is

applied to its maximum capacity. This is perfectly fine in factory form or even slightly modified vehicles, but it might be a weak point when the vehicle is exposed to more

demanding conditions.

With the SunCoast 10L1000 Valve Body, the required pressure to fully engage the regulator is decreased to only 80psi. This is a 33% decrease in pressure needed to

engage the clutch regulator valve (latch valve), leading to quicker shift apply when engaging clutches A, B, C, and F. In addition to reducing shift times, this faster

engagement lowers the heat generated in the clutch pack, preventing premature degradation and increasing clutch life. To improve this shift calibration further,

SunCoast is evacuating non-critical oil to raise apply rate.

With this new SunCoast pump/valve body combination, the factory total line pressure has been modified. The total main line pressure has increased by up to 60 psi

thanks to SunCoast. This enhanced line pressure raises the total pump volume production in addition to the maximum clamping force of the clutch packs. The SunCoast

10L1000 Valve Body has an integrated bypass to release excess pressure above 420 psi, minimizing the chance of runaway pressure and clutch fiber over-compression.

FEATURES:

Improved Clutch Wear

Shortened Shift Times

Increased Lock-Up Apply Pressure

250% Increase In Cooler Charge Pressure

Increased Line Pressure, As Much As 60psi

Increased Clamping Force On All Clutch Packs

33% Decrease In Maximal Pressure Actuation Of Clutch Packs

Note: For maximum results in power levels exceeding 800HP, it is highly recommended that the TCC apply offset be changed in the factory file calibration.

Share